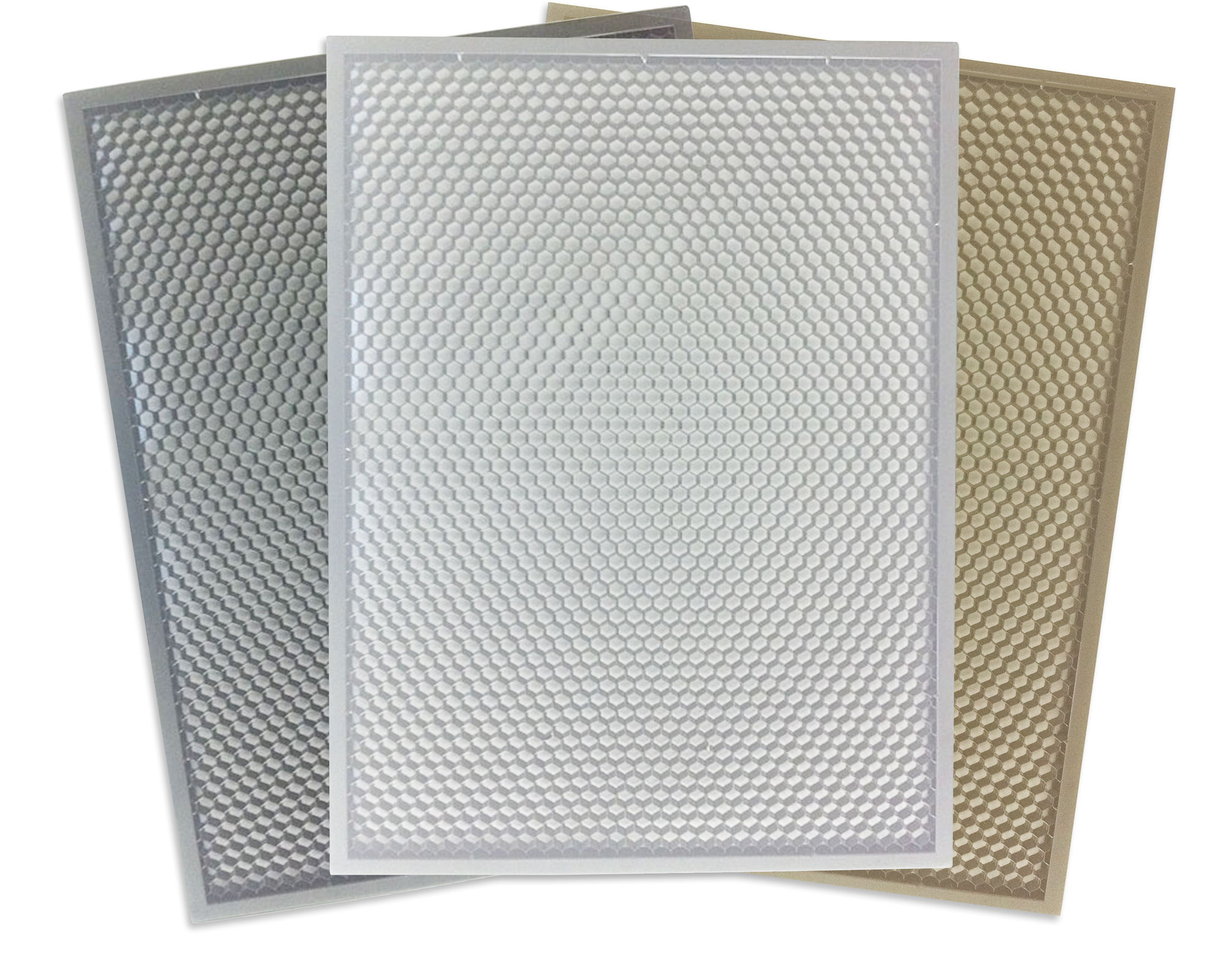

MATERIAL

The honeycomb structure can be made from a range of different metals including aluminium, mild steel, stainless steel, copper, etc

The material can be treated or coated with a wide range of other materials and the honeycomb cell structure can be empty or filled with any number of different materials depending on the intended use of the end-product.

STRUCTURE

The standard honeycomb structure is defined as follows:

- Hexagonal shape

- Array of hollow cells

- Thin vertical walls

- Arranged in columns

- Plate assembly

This coupled with the the metal used for the honeycomb, whether the cells are empty or filled (e.g. with a foam or epoxy) and the type and design of frame used to contain the honeycomb assembly will uniquely define the properties of the end-product.

PROPERTIES

The main properties to consider include:

- Weight

- Strength

- Air or Water Flow

- Thermal Conductivity

The relative density is proportional to the wall thickness to wall length ratio (t/L) and the Young’s modulus is proportional to (t/L)3

The mechanical properties of honeycombs depend on its cell geometry, the properties of the material from which the honeycomb is constructed (often referred to as the solid), which include the Young’s modulus, yield stress, and fracture stress of the material, and the relative density of the honeycomb.

- Aluminum honeycombs possess the highest strength to weight ratio, unmatched by any other structural materials.

- Stainless Steel Honeycombs are ideal for hostile environments and are used in train doors and floors, bulkheads, and other areas.

APPLICATIONS

-The unique structure and properties of the honeycomb metal product make it ideal for a range of applications applied across different industries. For example:

- Aerospace industry

- Marine Industry

- Automotive and Locomotives – radiator protection on earth-moving equipment

- Military

- Construction

- Packaging

- Sporting goods

- Air or liquid flow straighteners – change turbulent flow to laminar flow

- Filters / Sieves for water treatment

- Mining

The full potential for use in diverse applications has not yet been fully realised, but potential uses include ingress shielding of the aluminium radiator cores for quarrying applications; grilles for air conditioning inlets or return air-flow; durable filters for large particles, equipment bund stands to allow flow of excess liquids while ensuring a strong and stable base for the equipment; water drain or outlet cover; high strength Faraday-cage for large transformers to prevent electrical interference.

If you can think of an application that applies to your industry, give us a call and we will be happy to work with you to design and develop a honeycomb product that meets your needs.